ENGINEERING & QUALITY CONTROL

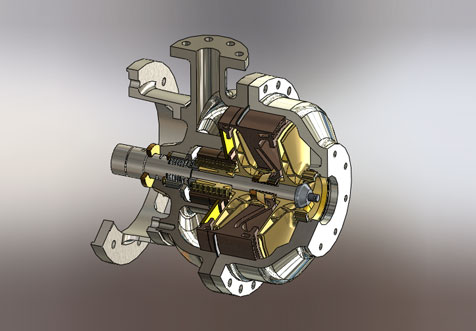

CAD

At CRYO-MACH we use only the latest CAD (computer aided drafting) software and computer technology in order to ensure being on the cutting edge of product design. By modeling our products, especially our volute housings and impellers with great accuracy, we can confidently push the envelope in pump design.

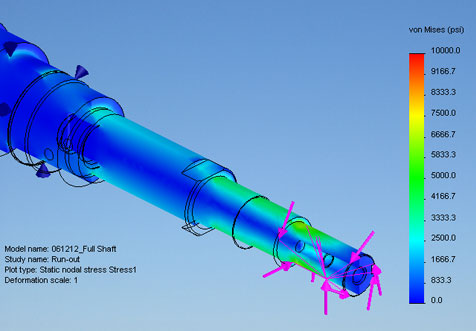

FEA

We utilize FEA (finite element analysis) software for a number of products and as a first step towards real world testing. By combining theoretical and practical analysis, we are able to offer a wide range of pumps that suit the ever-increasing demands and challenges of our customers and the cryogenic industry.

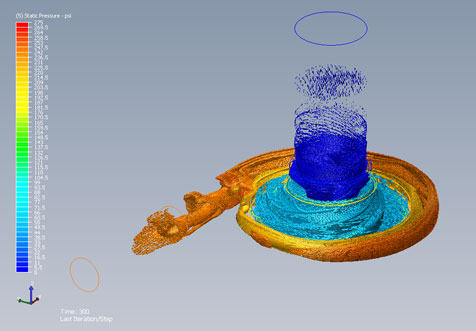

CFD

CFD (computational fluid dynamics) is a critical tool in evaluating all of our pumps.This complex and relatively new technology allows us to cover a multitude of design iterations before moving forward with physical prototype testing.

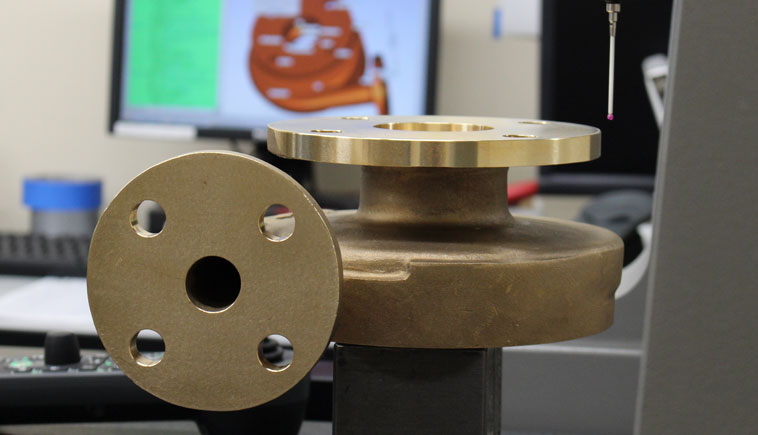

CMM

Our computer controlled CMM (coordinate measuring machine) is used to rigorously inspect 100% of all parts and its results are carefully verified by a quality control engineer. We incorporate a wide range of fixtures used to position the parts in order to guarantee the most accurate and reliable inspection data.

O2 CLEANING & INSPECTION

Every pump and part we offer is cleaned and inspected for oxygen service regardless of whether or not the item is eventually used for this service. This type of cleaning and inspection involves the most stringent protocols of all the cryogens our products are used with.

Made in the USA. Est. 1969

Made in the USA. Est. 1969