ABOUT

We manufacture and repair cryogenic horizontal centrifugal pumps and seals for liquefied gases.

COMPANY HISTORY

Cryogenic Machinery Corp. was founded in 1964, incorporated in 1969 and quickly became a notable player in the world-wide cryogenics industry. By adopting only the highest standards of engineering and manufacturing as well as assembly and inspection, CRYO-MACH has managed to stay competitive in an ever-changing market place.Never one to rest on our laurels, we are committed to constantly striving to improve our products as well as our customer support. In fact, this attention to our customers’ specific needs in addition to excellence in other areas has given CRYO-MACH an edge against global rivals for nearly 50 years.

ZACK SWARTZ

General Manager Zack Swartz leads the Sales, Marketing and Customer Success efforts for Cryogenic Machinery. Growing up in his father’s manufacturing business, Zack was taught, at an early age, the important value of listening to and taking care of your customers. After graduating from the University of Southern California, Zack moved to the Bay Area and led a Sales organization for one of San Francisco’s fastest-growing software companies, helping them achieve $100mm revenues. After almost a decade in the startup world, Zack decided he wanted to bring his expertise back to a small manufacturing company. He met Peter Ungar through a mutual friend and quickly decided CRYO-MACH would be his new home.

Zack Swartz leads the Sales, Marketing and Customer Success efforts for Cryogenic Machinery. Growing up in his father’s manufacturing business, Zack was taught, at an early age, the important value of listening to and taking care of your customers. After graduating from the University of Southern California, Zack moved to the Bay Area and led a Sales organization for one of San Francisco’s fastest-growing software companies, helping them achieve $100mm revenues. After almost a decade in the startup world, Zack decided he wanted to bring his expertise back to a small manufacturing company. He met Peter Ungar through a mutual friend and quickly decided CRYO-MACH would be his new home.

PETER UNGAR

Chairman Peter Ungar started working part time at Cryogenic Machinery when he was only 15, assisting his step father, Peter Fritz, during the early years of the business. He learned the techniques of building and repairing cryogenic pumps as well as many other tasks from the ground up. Upon graduation and having always had a fascination with aircraft, Peter went to trade school and obtained his A&P (airframe and power plant) license. After a brief time working as an aircraft mechanic he decided he’d rather design them and pursed a higher degree.

Peter Ungar started working part time at Cryogenic Machinery when he was only 15, assisting his step father, Peter Fritz, during the early years of the business. He learned the techniques of building and repairing cryogenic pumps as well as many other tasks from the ground up. Upon graduation and having always had a fascination with aircraft, Peter went to trade school and obtained his A&P (airframe and power plant) license. After a brief time working as an aircraft mechanic he decided he’d rather design them and pursed a higher degree.

Having achieved a BSME, Peter went to work for McDonnell Douglas Aircraft Company and diligently learned the high standards of the industry. After several years, his previous and newly acquired knowledge and skills were requested and put to the test at Cryogenic Machinery. During his second tenure, Peter meticulously studied the field of cryogenic centrifugal pump engineering, in addition to tackling sales and managerial tasks. In 2008, Peter rose to the positions of CEO and President. In 2018 Peter moved into the role of Chairman.

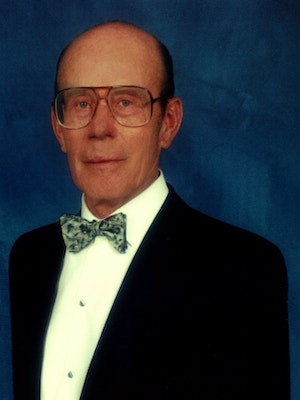

PETER FRITZ

Founder Peter Fritz, our founder, was born in Hungary and immigrated to the United States during World War II. Arriving here with little more than a MSME and sheer determination, he furthered his engineering knowledge at Drexel University. While working at Ingersoll Rand, Mr. Fritz expanded his centrifugal pump expertise under the guidance of pump luminary Alexey J. Stepanoff. He then moved to the west coast and became lead design engineer at a cryogenic pump company. After dealing with the frustrations of two layoffs and knowing it was time for a serious career shift, Mr. Fritz decided to forge his own path as a cryogenic pump and seal consultant.

Peter Fritz, our founder, was born in Hungary and immigrated to the United States during World War II. Arriving here with little more than a MSME and sheer determination, he furthered his engineering knowledge at Drexel University. While working at Ingersoll Rand, Mr. Fritz expanded his centrifugal pump expertise under the guidance of pump luminary Alexey J. Stepanoff. He then moved to the west coast and became lead design engineer at a cryogenic pump company. After dealing with the frustrations of two layoffs and knowing it was time for a serious career shift, Mr. Fritz decided to forge his own path as a cryogenic pump and seal consultant.

His success in consulting lead to the development of ground-breaking cryogenic seal innovations and was quickly followed by equally innovative cryogenic pump designs. The rest, as they say, is history. Peter Fritz used his vast knowledge, experience and unwavering perseverance to boldly put his stamp on the world of cryogenics. His vision, integrity and standards of excellence laid the foundation of a company that continues to design, manufacture and repair cryogenic centrifugal pumps and seals to only the highest standards in the industry.

Made in the USA. Est. 1969

Made in the USA. Est. 1969